technology

![]()

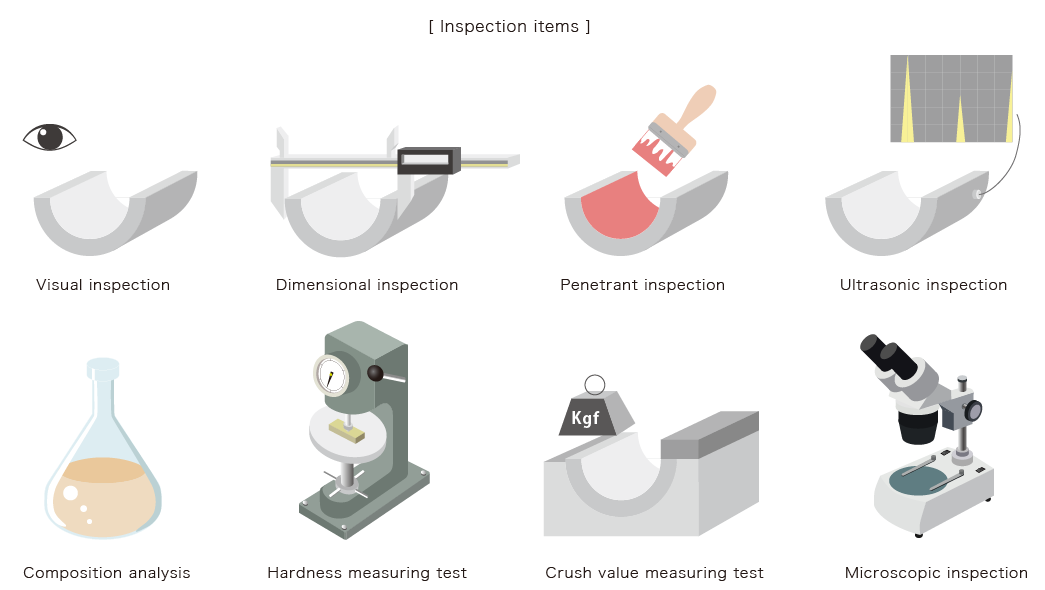

05 Inspection

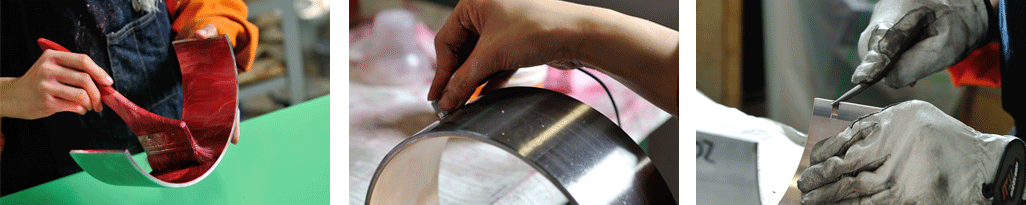

The bearings completed through a variety of processes are inspected based on the specifications for each product type. The inspection process includes visual inspection, dimensional inspection, penetrant inspection, ultrasonic inspection, composition analysis and hardness measuring test. Furthermore, there is the crush value measuring test added as a feature of thinner type bearings, which is regarded as one of the important inspection processes at Isoda Metal. In addition, we also conduct the microscopic inspection in order to confirm structure of the alloy. This test is carried out to verify whether or not the alloy was casted in the ideal conditions, and is also regarded as an important inspection process as it is related to the rotation speed and the cooling temperature applied during the centrifugal casting.